FY-hengfa nonwoven Fabric series: PET Polyester Spunbond Non woven, Meltblown Nonwoven, Activated Carbon Nonwoven Fabric, Nonwoven Filter Bag,Nonwoven Fabric For Auto Filter.

Such as:

100% PET/PP spunbond nonwoven fabric.

It is similar to filament yarn production. From the chips storage, the polymer is vacuum-fed to a dosing station on top of the extruder. Inside the extruder, it becomes melted and homogenized. Passing a filter system and a spin pump, the melt is fed into the spin beam or spinnerets, which form a curtain of filaments. The filaments are cooled by means of a stream of air in a blowing area, drawn by aerodynamic forces and then transported to the downstream discharge channel. For nonwovens, instead of a further stretching process for filament yarns, the filaments are swirled around and then deposited on the wire mesh belt as a random nonwoven. This web is transferred to a bonding calender that uses heat and pressure to set such physical properties as tensile strength and elongation of the final product. After cooling, the material can be wound.

Product :Spun-bonded Nonwoven

Material :100% polyester

Width :0.15-3.20m.

Specification:1000M-4500M/roll or customized

Weight :10gsm-260gsm

Use :

1. Medical : face mask ,surgical cloth ,bedsheet ,disposable cap , shoose cover .

2. Packing : shopping bag , tablecloth ,wallpaper ,compund packing material .

3. home textile : pillow case ,mattress cover ,linling .

4. Industry : protect the crop from insect .cold weather .filtration materials

Non Woven Fabric Non Woven Fabric,Pet Non Woven Fabric,Activated Carbon Nonwoven Fabric Hebei Fangyu Trade Co., Ltd. , https://www.filtersmaterial.com

The Rice Water Polisher machines used to remove the dust of bran from the rice and polish the rice surface by spraying water through the mixing chamber and by creating friction among rice grains using milling rollers. The weight controlled outlet of the polisher controls the retaining time of kernels inside the milling chamber.

Our Rice Water polisher equipped with water pump and air pump as well as automatic water (moistening)control device with constant to avoid any blockage due to excessive water content. This machine can operates with rice mill unit and independently operates for deep processing of the rice.

Our Single Polishing Roller Mist (Water) Rice Polisher is a newly rice polisher adopting dampening with compressed air spraying. The polisher is with unique structure of polishing chamber, which can produce polished white rice with high accurate according to customers requirements. The dampening device adopted atomizes water into corpuscular water mist which is uniformly applied on to the surface of the whitened rice, increased shine, less rice broken and lower rice temperature.

We also provide Double Rollers Rice Water Polishers. This kind of water polisher comes with novel design, compact structure, easy and convenient operation, small floor area. An axial double air intake mode and an intensive exhaust system are used, to sufficiently remove bran from rice surface, so that the surface of polished rice can be bright and sparkling, and its preservation period can be prolonged.

The surface of polished rice becomes lucent and white according with modern rice polishing requirements of new notion, it make the rice looks more smooth and bright. Due to good appearance and very steady mechanical performance, our rice water polishers are more and more welcomed as a piece of ideal equipment for processing clean rice product.

1. Product description

FMP series rice polishing machine is a new generation rice machine that collected professional skills and merits of internal and overseas similar productions. Its structure and technical data are optimized for many times to make it take the leading place in the polishing technology with considerable effect such as bright and shining rice surface, low broken rice rate which can completely meet the users' requirements for producing non-washing high-finished rice (also called crystalline rice), non-washing high-clean rice (also called pearl rice) and non-washing coating rice (also called pearly-luster rice) and effectively improve the quality of the old rice. It is the ideal upgrading production for modern rice factory.

2. Features

1. Designed and manufactured by using two patent technologies, built-in motor, small floor area and beautiful profile;Â

Model

FMP-8T Water Polisher

FMP-9T Water Polisher

Capacity(kg/h)

6500-7500

7500-8500

Air volume(m3/h)

5800-6600

6400-7200

Static Pressure(PA)

3000-3500

3000-3500

Power(kw)

75.90

55*2

Dimension(LxWxH) (mm)

2242*1020*2298

2569*1270*2393

4. Photos

5. Contact us

Ms. Danni Feng

Hubei FOTMA Machinery Co., Ltd

Add: No. 52 Guanggu Avenue, New High-tech Development Zone, Wuhan city, Hubei Province, P. R. China.Â

Web: www.chinaricemill.com

Tel: +86 27 67848665, +86 27 18202720898

Non Woven Fabric

Automatic Rice/Paddy Water Polisher (FMP Series)

Model NO.: FMP

Condition: New

Customized: Customized

Model: FMP

Capacity(t/h): 8-9

Power(kw): 75.9-110

Rotation Speed(rpm): 980

Dimension(L*W*H) (mm): 2242*1020*2298

Trademark: FOTMA

Transport Package: in Wooden Case

Specification: EEC EPA

Origin: China

HS Code: 8437109000

Automatic Rice/Paddy Water Polisher (FMP Series)2. Jet-air and air locking technique with double pressure gates, the air volume passing through the whitening chamber is above 2.5 times more than that of normal rice whiteners and rice temperature rise can be restrained effectively;Â

3. Equipped with aspirating device for material feeding and discharging, dynamic cooling the white rice, low temperature of discharged rice, low bran content and little broken rice;Â

4. Double feeding gates with magnetic separating devices, fine adjustment of flow rate;Â

5. Unique design of rotary whitening chamber, convenient and quick replacement of rice screens;Â

6. Unique double rolls designed side by side, simultaneous feeding and high output. Â

Â

3. Technical parameters

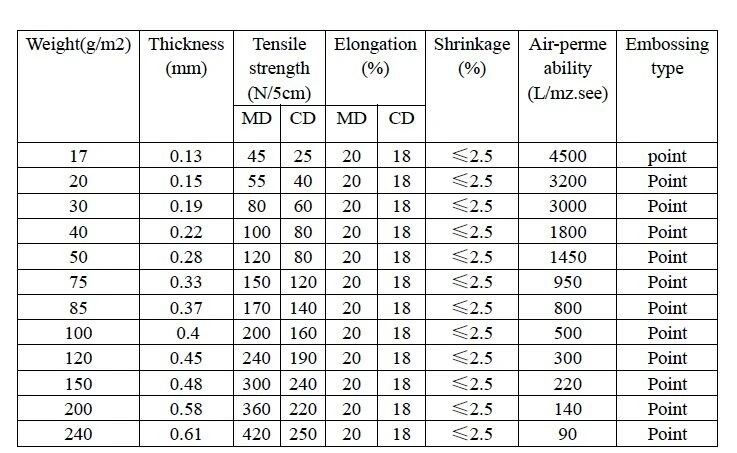

Product Data Sheet