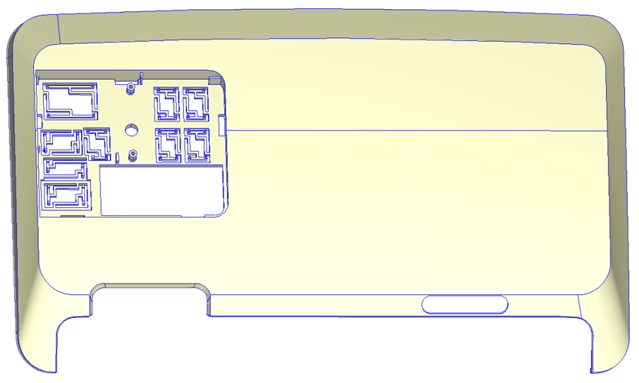

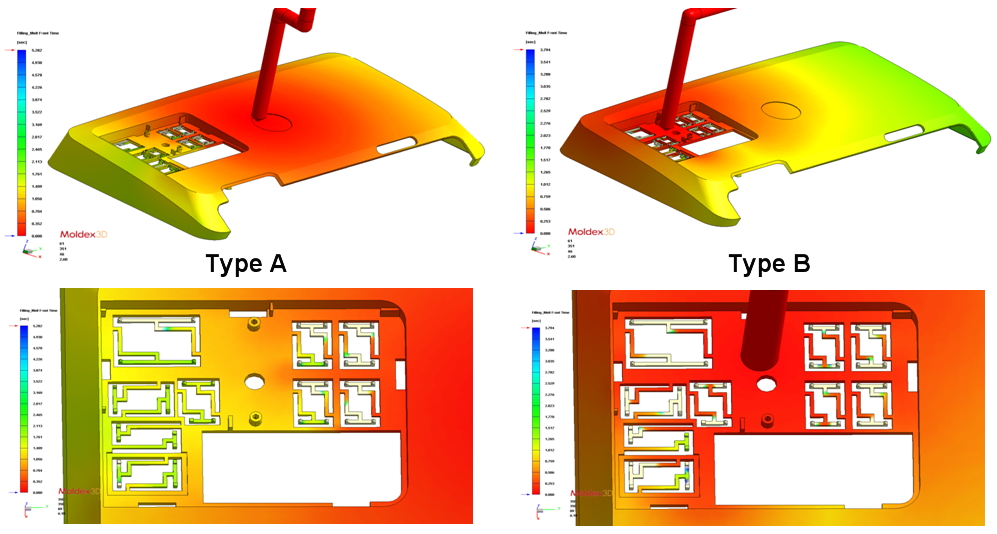

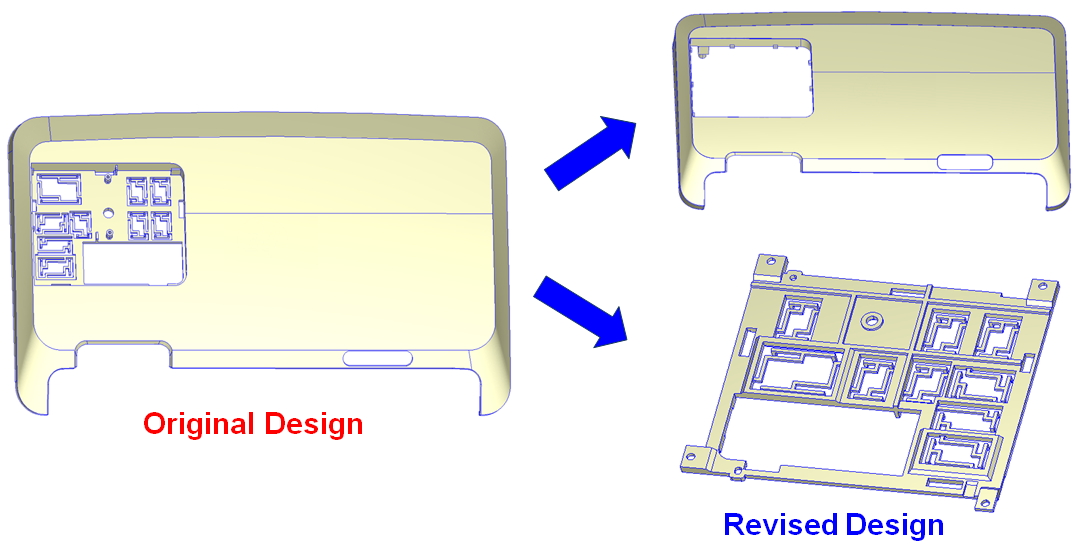

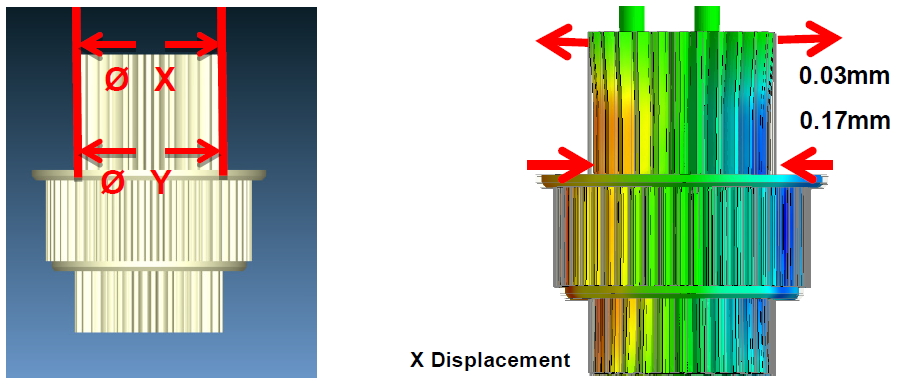

In the first case, the scanner cover contains grid structure with tiny features (Fig. 1). This is a challenge in injection molding and can easily cause short shot and weld line issues. To control the cost of design revision and tooling, it requires a better understanding of the product moldability at the early design stage. In the second case, the gear of the scanner requires more stringent dimensional requirements for proper functions as well as good surface finish (e. g. gating area) for accurate assembly. Moldex3D supports early diagnosis of different molding defects and provides optimization on molding performance. Applying Moldex3D filling analysis to evaluate short shot and flow imbalance issues, and utilizing packing and cooling analyses to evaluate the impact of part shrinkage and over-packing The first case of a scanner cover is to evaluate if revising gating designs can help resolve the short shot problem caused by tiny features in the grid structure. Moreover, Foxlink had to predict the final dimension of a molded scanner gear and find the major issue for design revision to meet product criteria. First, they utilized Moldex3D simulation to evaluate two gating designs for the scanner cover (Fig. 2, from the grid structure or center area), and found similar short shots in both cases, thus, the designer decided to mold the component parts separately (Fig. 3). Foxlink decided to mold the scanner cover components separately since there’s no viable solution to solve the short shot. In the scanner gear case, the simulation results showed flow imbalance and over-packing issue, resulting in part deformation and failure on dimension criteria (Fig. 4). Foxlink proposed 3 design revisions in order to improve the part deformation issue (Fig. 5) After verifying the original design and revised designs through Moldex3D Filling/Packing/Cooling, Foxlink found that gating relocation, parting face shift and part design change on local thickness are required in order to effectively resolve the flow imbalance and over-packing problem on the molded scanner gear so that the dimension after deformation would be greatly improved. The actual molding results showed that Type C can improve filling pressure, result in fewer packing pressure losses and improve heat accumulation as well as uneven part shrinkage. Moreover, the actual difference between the upper and lower part of the gear opening (Ø X & Ø Y) fell around 0.03mm, which met the design criteria and was correspondent with the simulation prediction (Fig. 6). Moldex3D can help achieve tooling with much lower cost and provide early diagnosis of molding defects, such as short shots, air traps, sink marks and warpage, and further help save significant amounts of production money and mitigate risks before the actual production. Shopping Bag,Non-Woven Printed Shopping Bags,Waterproof And Reusable Shopping Bag,Non-Woven Shopping Bag Guangzhou Ecobag Packaging Co., Ltd , https://www.gdecobag.com

Executive Summary

Fig. 1 The scanner cover with grid structure and tiny features is challenging during injection molding

Challenges

Solutions

Benefits

Case Study

Fig. 2 The short shot issues on different gating design are evaluated through the flow front result in Moldex3D Filling analysis

Fig. 3 It shows short shot risk no matter which gating design was applied, hence, it was suggested to mold as two seperated parts

Fig. 4 The difference of the upper and lower part (Ø X & Ø Y) of the scanner gear has to meet required dimension criteia

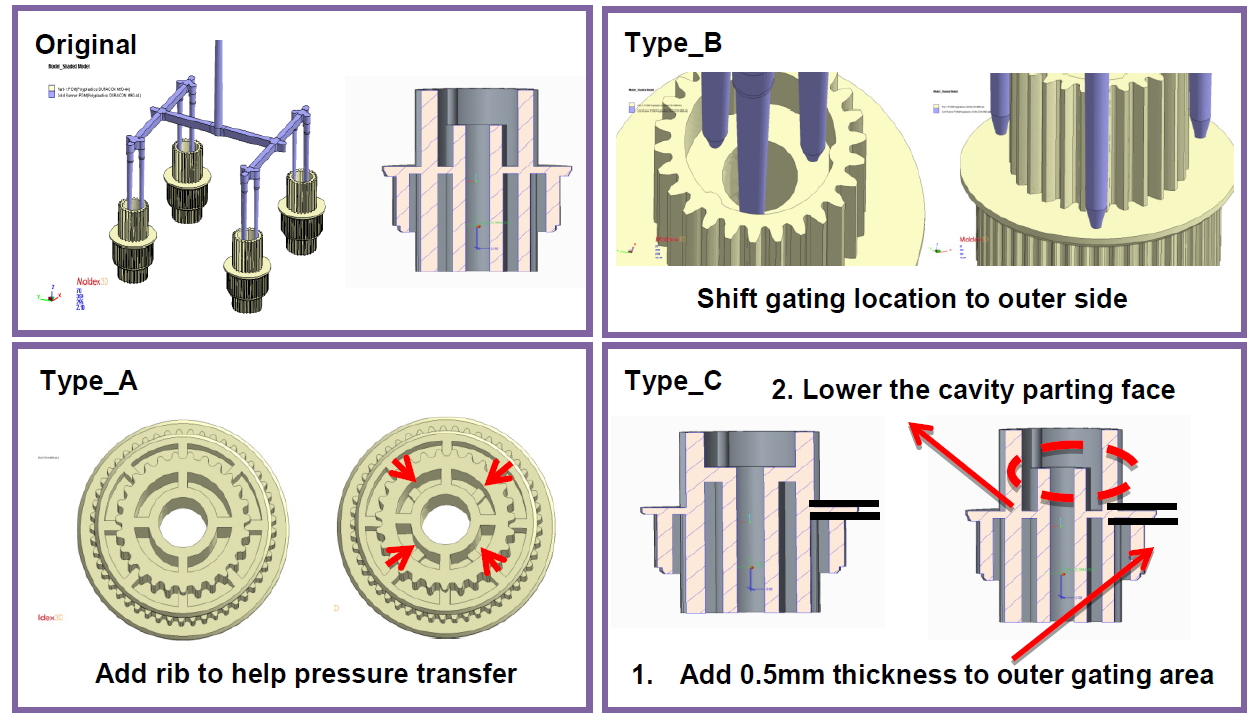

Fig. 5 Three different revised designs were proposed to improve the part deformation of the scanner gear

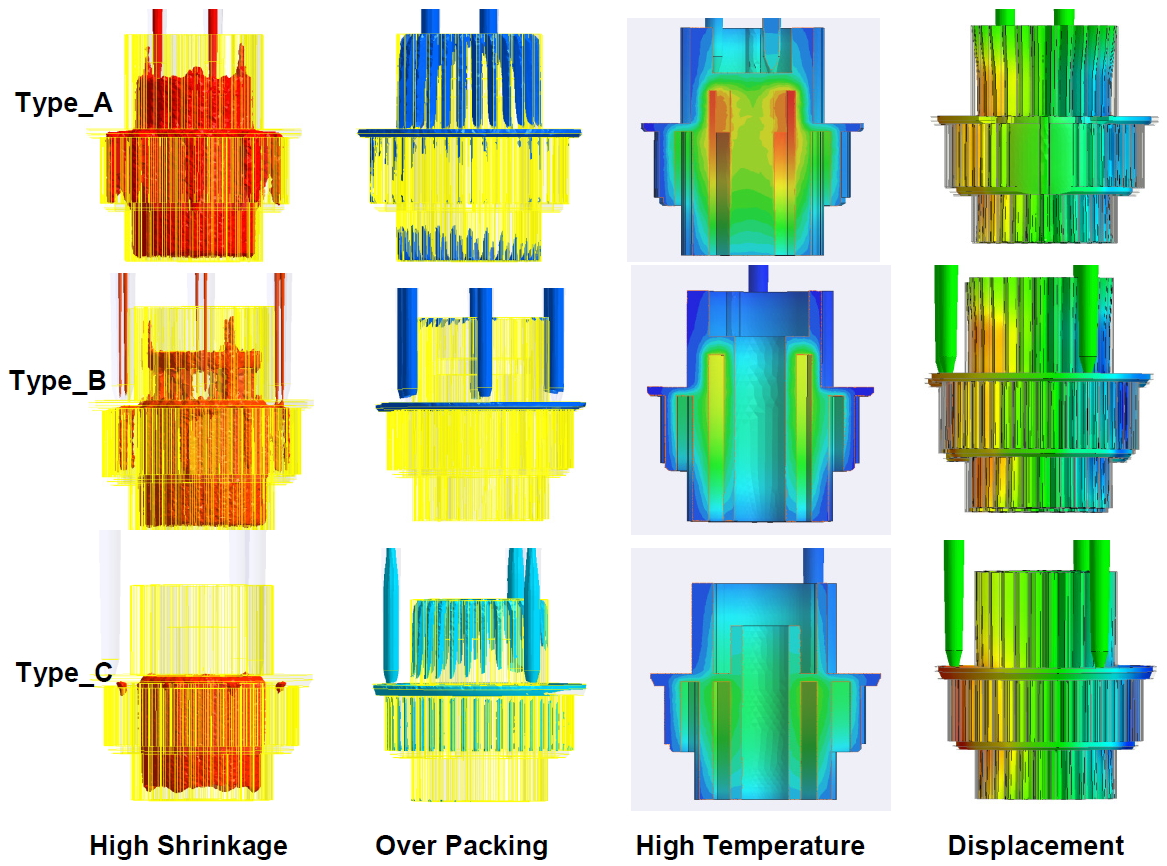

Fig. 6 The packing and part deformation simulation results of the revised designs

Results

Design Evaluation and Optimization Prior to Scanner Component Tooling

Customer Profile