The laser cutting machine has revolutionized the manufacturing industry by providing precise and efficient methods for cutting various materials. Central to this groundbreaking technology is the software that drives its operations. Laser cutting software refers to the computer programs and systems that control the laser cutting machines. Software in laser cutting machines plays a critical role in determining the precision, efficiency, and overall performance of the cutting process. Advanced laser cutting software integrates features like automatic nesting, real-time monitoring, and precise control over laser power and speed. Ensuring software compatibility with the specific type of laser-cutting machine is crucial. Compatible software will support the necessary file formats, provide the required vector or raster data, and integrate seamlessly with the machine's firmware. This compatibility ensures smooth operation, reduces the risk of errors, and enhances the machine's overall performance. This guide explores various laser-cutting machine software, highlighting key features to help users make informed decisions. It reviews top software solutions, offering insights into their benefits and drawbacks. The guide also provides advice on choosing the right software for different needs, alongside installation tips and troubleshooting. By the end, readers will understand how to use laser cutting software to enhance manufacturing processes, improve precision, and boost efficiency. Design software, also known as CAD (Computer-Aided Design) software, is the starting point for the laser cutting process. CAD software allows users to create and manipulate digital models, which serve as the blueprint for the laser cuts. Popular design software includes Autodesk AutoCAD, SolidWorks, and CorelDRAW. These programs offer a range of features, from basic vector drawing and editing tools to advanced 3D modeling capabilities. The choice of design software often depends on the complexity of the project and the specific requirements of the task at hand. CAM (Computer-Aided Manufacturing) software bridges the gap between design and production. This type of software converts CAD designs into machine-readable code, often in the form of G-code, that the laser cutter can execute. CAM software typically includes features for toolpath generation, nesting, and simulation. Examples of CAM software include Fusion 360, Mastercam, and VCarve Pro. Effective CAM software ensures efficient material usage, accurate cuts, and optimal machine performance by calculating the best cutting paths and parameters. Control software, often embedded within the laser cutting machine's system or provided by the machine manufacturer, is responsible for executing the cutting process. This software directly communicates with the machine’s hardware, managing the movement of the laser, the worktable, and other mechanical components. Control software handles the real-time processing of instructions, adjusts feed rates, and monitors system status to ensure precise and safe operations. Notable control software options include proprietary solutions tailored to specific machines, like Epilog's JobControl and Trotec's JobControl Vision. Simulation software plays a critical role in optimizing and validating the laser cutting process before actual production begins. By creating a virtual representation of the cutting operation, this software allows users to identify and rectify potential issues, such as collisions or inefficient cutting paths, without wasting material. Simulation software enhances productivity by reducing trial and error during the setup phase. Software like TruTops and Lantek Expert Cut offer robust simulation capabilities, helping users achieve accurate and efficient cutting outcomes. Nesting software is designed to arrange the parts to be cut in an optimal layout on the material sheet, maximizing material usage and minimizing waste. This type of software is particularly important in industries where material cost is a significant concern. Nesting algorithms calculate the best possible arrangement of shapes to fit within a given material area, resulting in cost savings and efficient production. Popular nesting software includes SigmaNEST, NestMaster, and ProNest, all of which provide powerful tools for material optimization. Certain industries require specialized laser cutting software tailored to their unique needs. For instance, the fashion and textile industry uses software like Optitex, which offers solutions for cutting fabric patterns. Similarly, the metal fabrication industry may utilize software like Metalix or BySoft, which are designed to handle the complexities of metalworking. Industry-specific software often includes features and functionalities that address the particular challenges and requirements of the sector, providing tailored solutions that enhance overall productivity. For beginners or budget-conscious users, open source and free laser cutting software options provide basic functionality without the need for significant financial investment. Programs like Inkscape (with the LaserCut plugin) and LaserWeb offer entry-level solutions for hobbyists and small businesses. The first step in choosing the right software is to clearly define your specific needs. Consider the following aspects: Ensure that the software you select is compatible with your laser cutting machine. Compatibility includes: A user-friendly interface can significantly impact productivity and reduce the learning curve. Consider software that offers: Look for software that offers the critical features outlined in the previous chapters. Key features to prioritize include: Consider software that allows for customization and can scale with your growing needs: Reliable customer support and an active user community are invaluable. Ensure the software vendor provides: Finally, balance the software’s features against your budget. While advanced software can offer significant benefits, there are also cost-effective alternatives: Many software vendors offer free trials or demo versions. Use these opportunities to test the software’s features and ensure it meets your operational requirements before making a final decision. For beginners, user-friendly software with intuitive interfaces and supportive resources is essential. LightBurn and LaserGRBL are excellent choices for novices. LightBurn offers extensive features tailored for laser cutting and engraving, while maintaining an accessible interface. LaserGRBL is a free, open-source option often favored by hobbyists due to its simplicity and ease of use. Both options provide sufficient functionality to get started without a steep learning curve. Yes, design software like Adobe Illustrator can be used with most laser cutting machines, provided the software supports the required file formats for the laser cutter. Adobe Illustrator can export files in formats such as AI, SVG, and DXF, which are commonly accepted by laser cutting software. However, it’s crucial to ensure compatibility between the design file and the laser cutter's control software. Tools like CorelDRAW and Inkscape are also popular for creating compatible vector designs for laser cutting. Calendar,Wall Calendar,Desk Calendar,Desk Pad Calendar Guangzhou Xinqicai Printing Co., Ltd. , https://www.cnxqcprinting.comI. Introduction

II. Types of Laser Cutting Machine Software

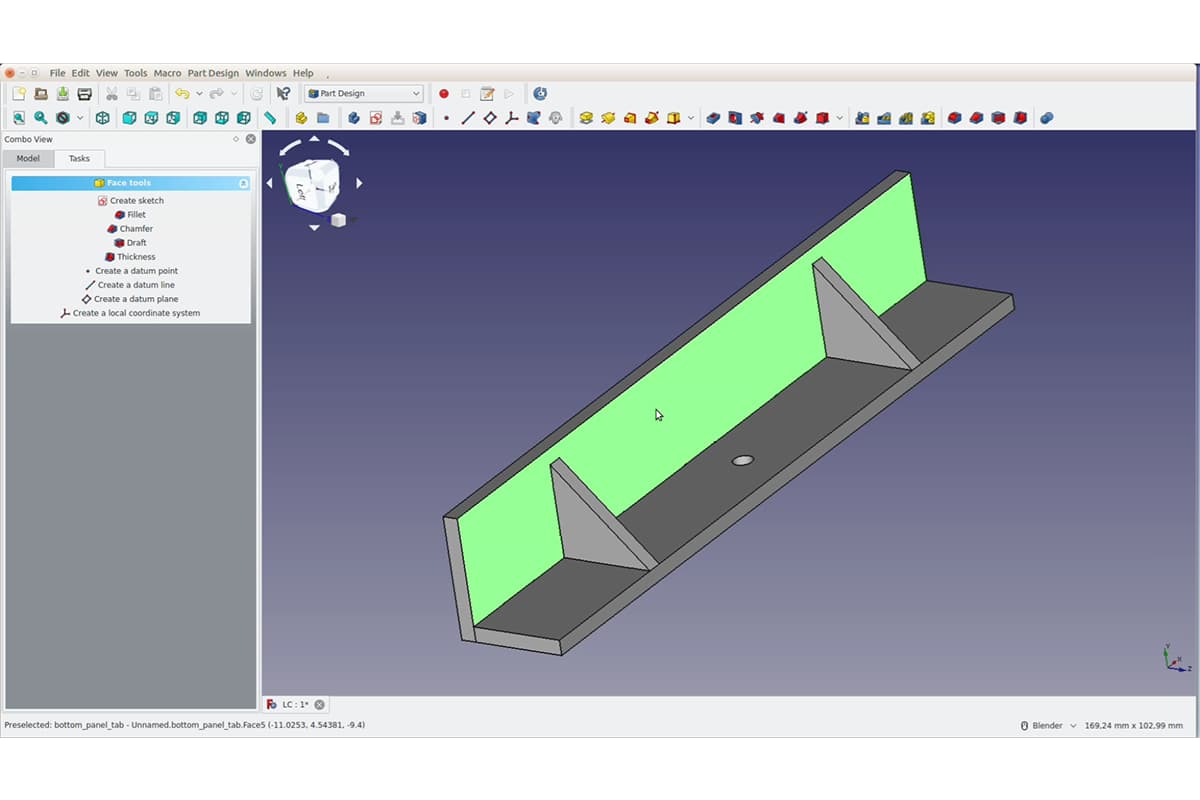

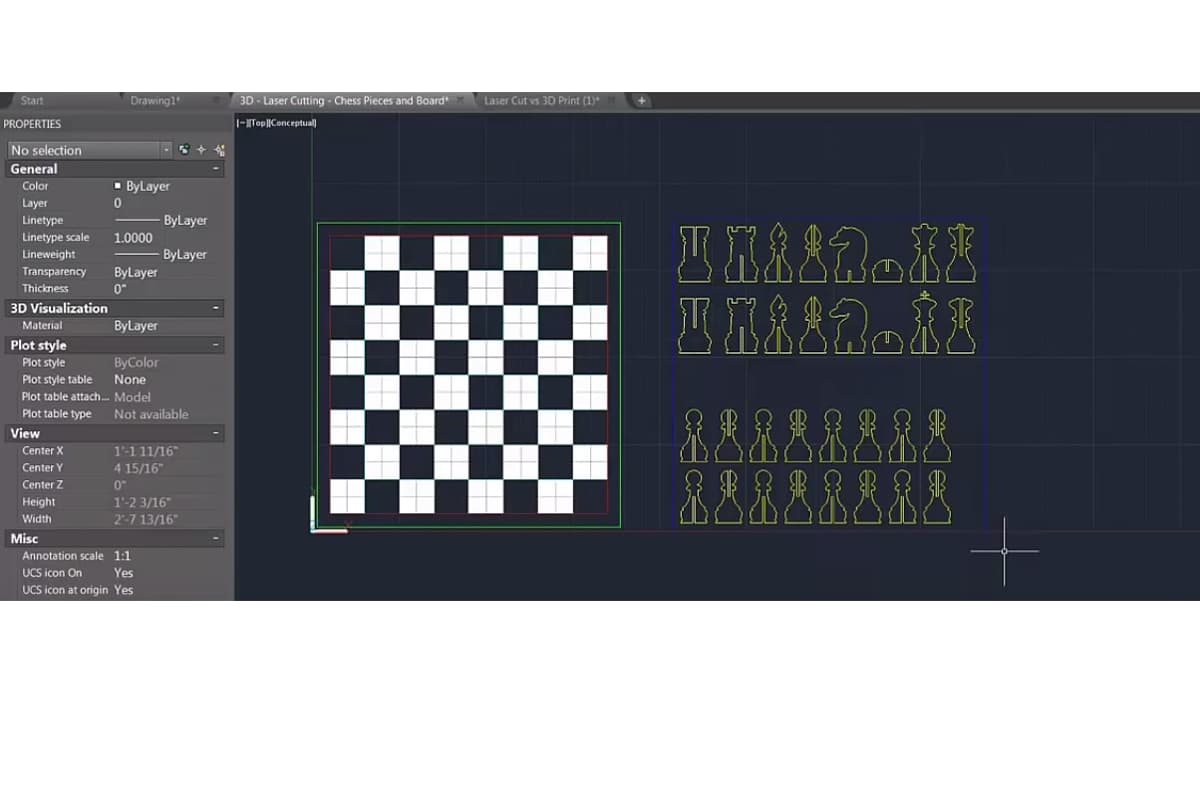

Design Software

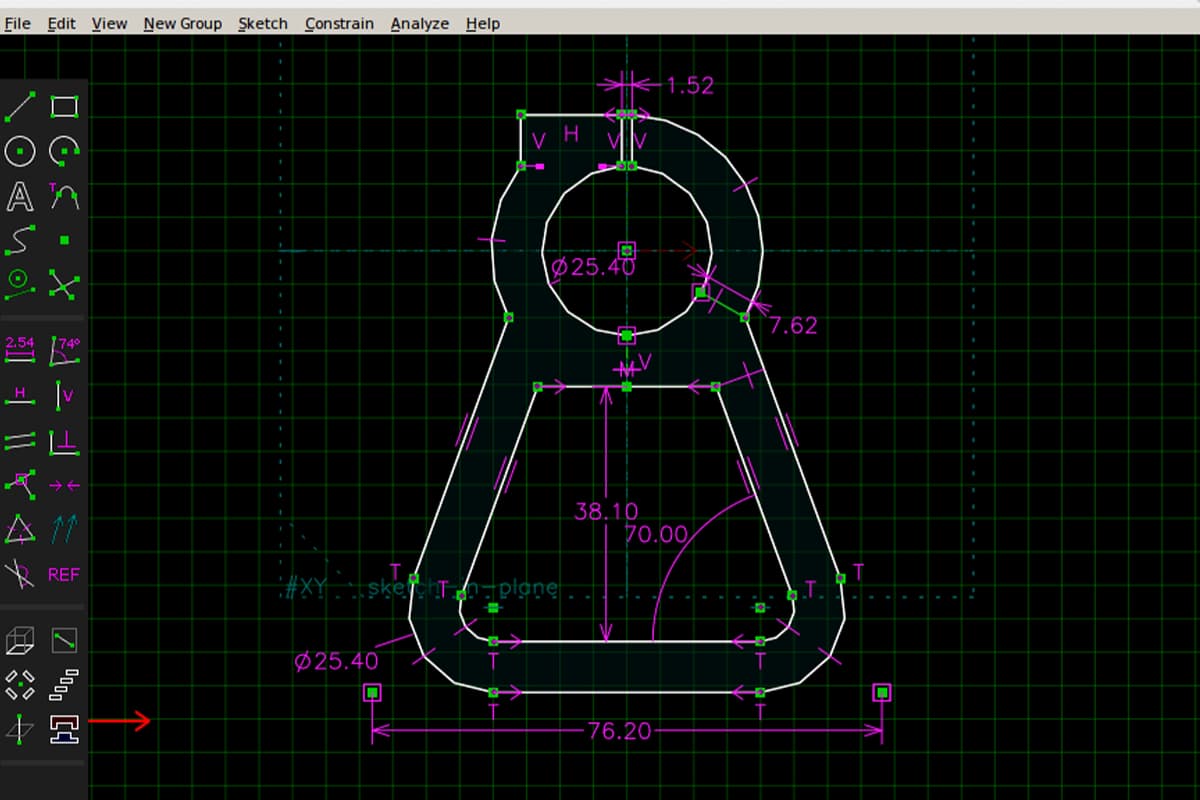

CAM Software

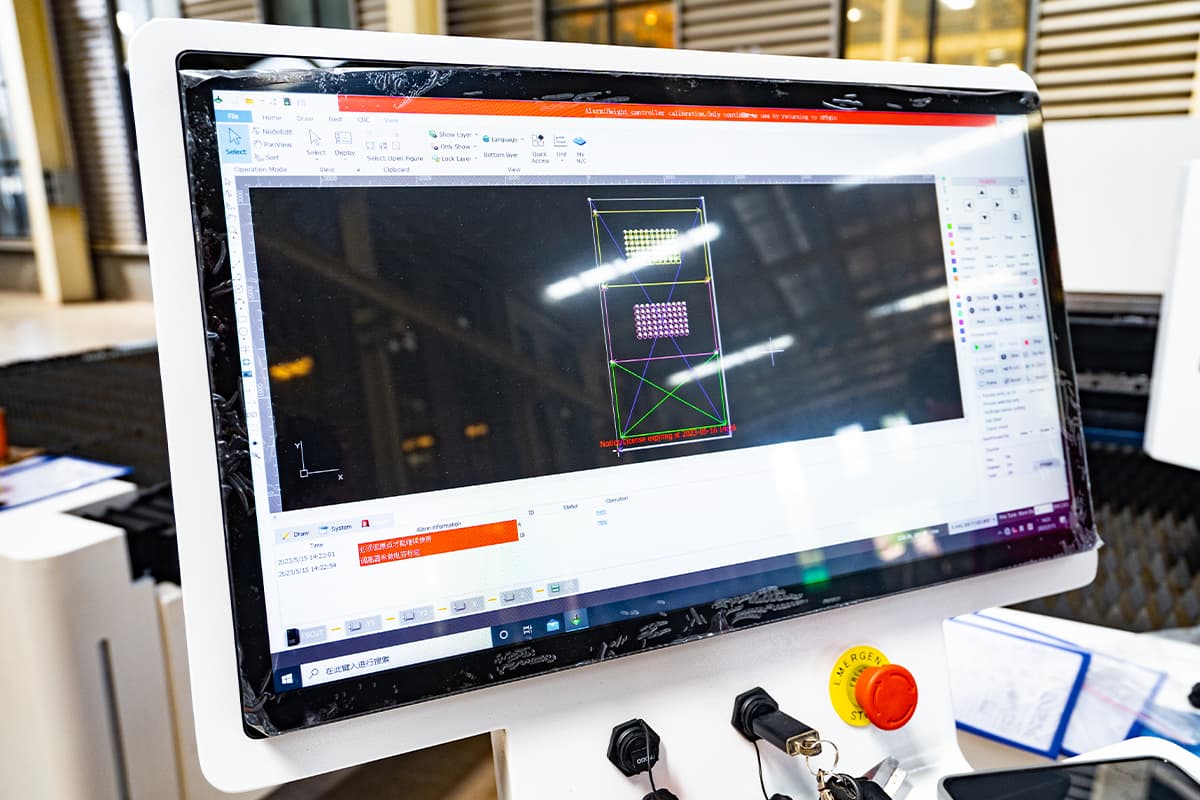

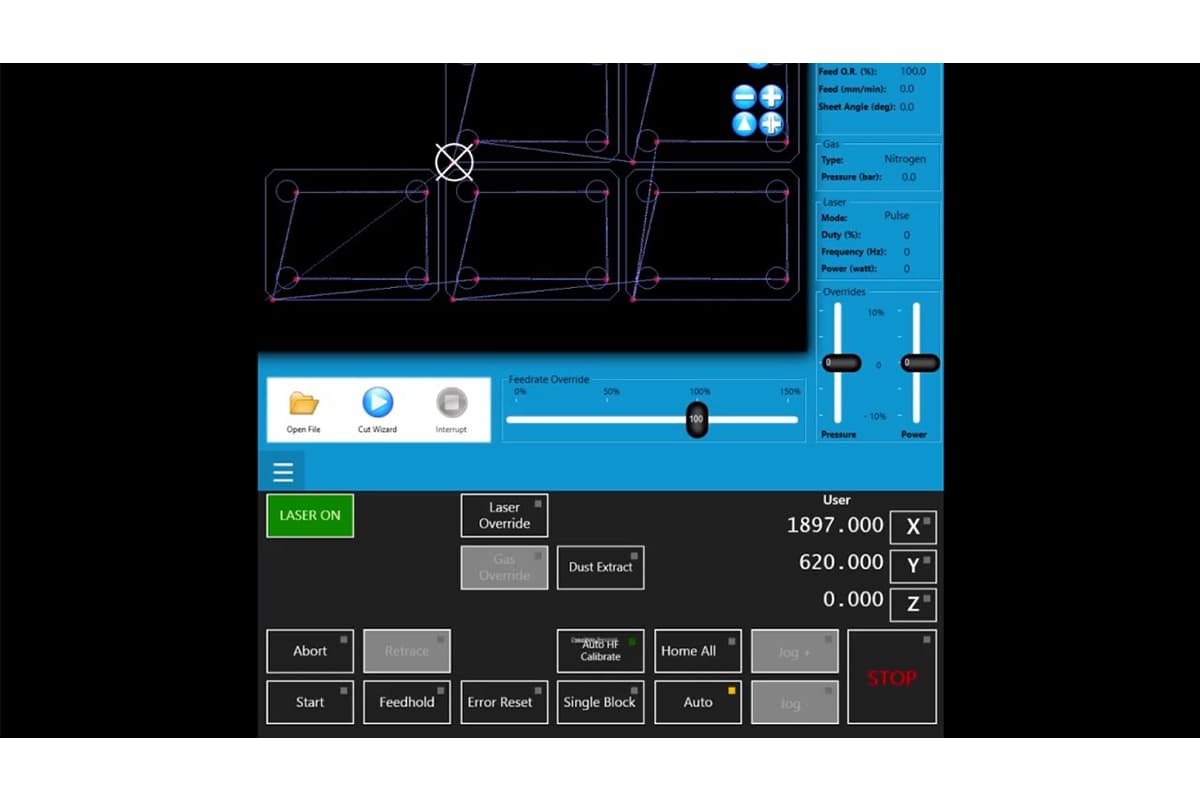

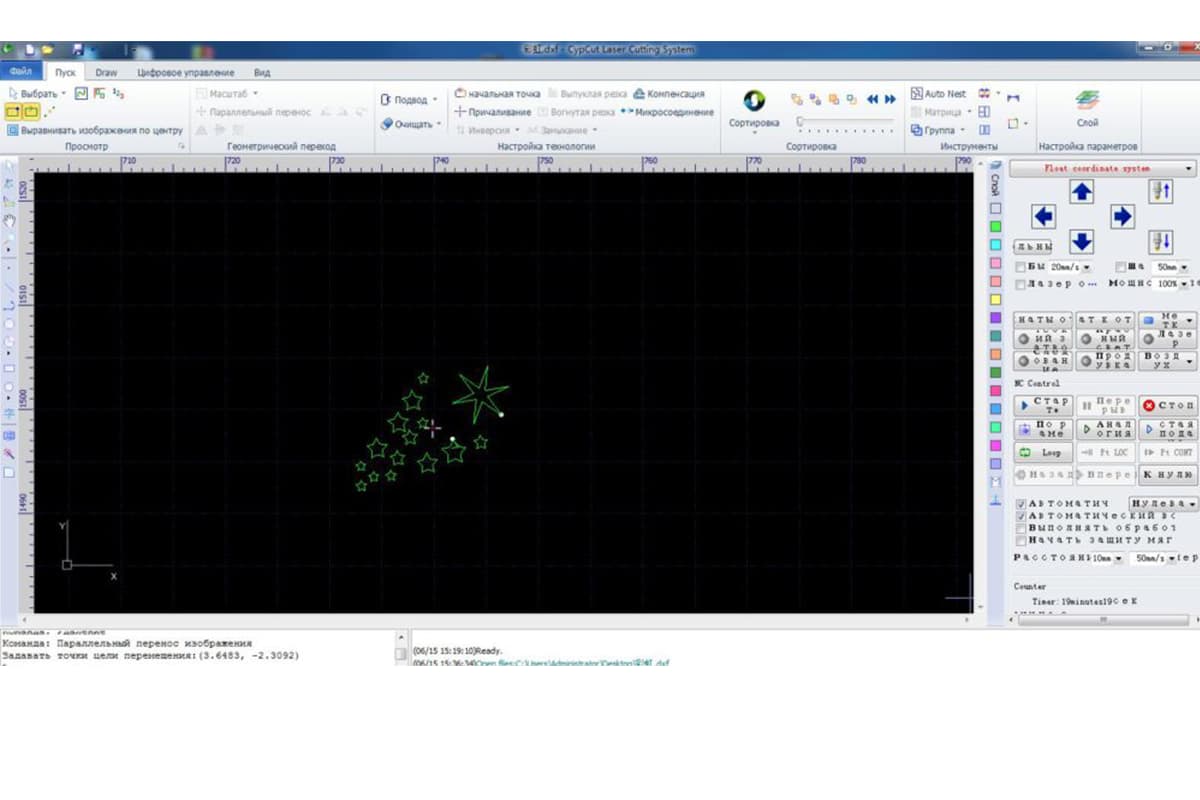

Control Software

Simulation Software

Nesting Software

Industry-Specific Software

Open Source and Free Software

III. Top Laser Cutting Software Solutions

1. LightBurn

2. RDWorks

3. Adobe Illustrator (with Plugins)

4. CorelDRAW (with Plugins)

5. Inkscape (with Laser Extensions)

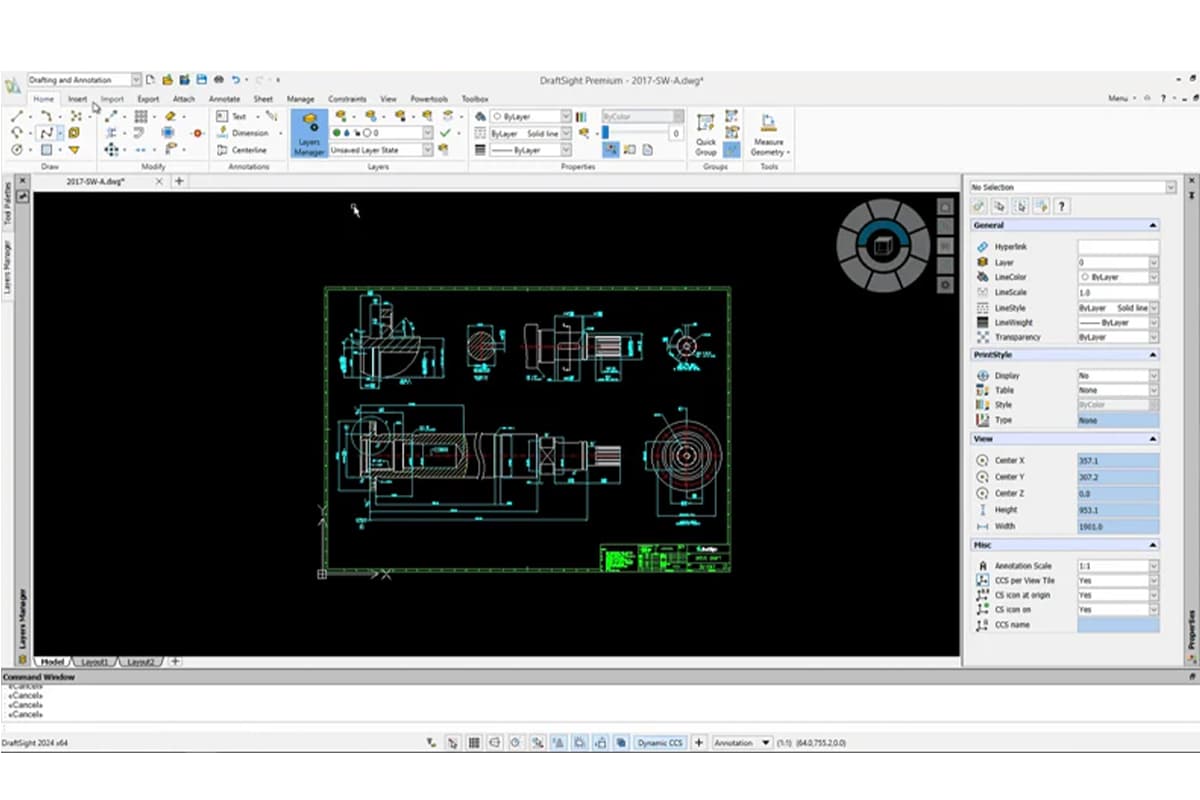

6. Autodesk AutoCAD

7. LaserWeb (Web-based)

8. Fusion 360

9. DraftSight

10. Glowforge App

IV. Key Features to Look for in Laser Cutting Software

Key Feature Description User-Friendly Interface A user-friendly interface is crucial for both beginners and seasoned professionals. The software should have an intuitive layout, drag-and-drop functionality, easy access to frequently used tools, customizable workspaces, clear visualizations, and user prompts to enhance usability and streamline workflow. Advanced Design Tools Robust design tools are essential for creating precise and complex geometries. Look for vector graphic support, layering capabilities, 3D modeling, compatibility with common CAD file formats (.DXF, .DWG, .AI), and features like parametric design for easy modifications. Material Database An integrated material database includes preset parameters for different materials, providing optimal laser power, speed, and settings. The ability to create and customize material profiles is beneficial for tailoring settings to unique or proprietary materials. Automatic Nesting Automatic nesting maximizes material usage and minimizes waste through effective nesting algorithms that optimize part arrangement on the material sheet. Configurable nesting options should account for different cutting strategies and material constraints. Simulation and Preview Capabilities Essential for validating the cutting process before production, simulation and preview capabilities allow visualization of the cutting path, detection of potential issues, and necessary adjustments. Reliable simulation tools provide feedback on cutting sequence, estimated cut time, and optimization areas. Compatibility with Hardware Ensure software compatibility with your laser cutting machine’s hardware and firmware, including support for communication protocols, file formats, and control commands. Verify compatibility to avoid operational disruptions and ensure smooth performance. Real-Time Monitoring and Feedback Real-time monitoring provides live updates on the cutting process (e.g., laser power, speed), helping operators make real-time adjustments. It aids in detecting issues like misalignments promptly, reducing downtime and improving efficiency. Customization and Scripting Customization enhances versatility through macro creation, custom toolpath strategies, and automation via scripting languages like Python. This allows tailoring software to specific project requirements, automating tasks, and integrating with other tools or workflows. Strong Customer Support and Community Reliable customer support and a strong user community are invaluable for resolving issues quickly. Access to documentation, tutorials, technical support, and an active user community for sharing tips and advice is beneficial. Regular Updates and Improvements Choose software from vendors committed to regular updates to ensure compatibility with the latest hardware advancements, incorporate new features, and address security vulnerabilities. Check the vendor’s update history and roadmap for ongoing development commitment. V. How to Choose the Right Software for Your Needs

Identify Your Specific Requirements

Evaluate Compatibility with Your Laser Cutting Machine

Assess User-Friendliness

Check for Essential Features

Evaluate Customization and Scalability

Review Software Support and Community

Consider Cost and Budget

Perform a Trial Run

VI. Installation Guide and Issues Troubleshooting

Step-by-Step Installation Guide

1. Preparation

2. Installation Process

3. Initial Setup and Configuration

Troubleshooting Common Issues

1. Installation Errors

2. Compatibility Issues

3. Software Crashes or Performance Issues

4. Connection Problems with the Laser Cutter

VII. Frequently Asked Questions

1. What is the best software for beginners in laser cutting?

2. Can I use design software like Adobe Illustrator with any laser cutting machine?

3. How do I ensure my laser cutting software is compatible with my machine?