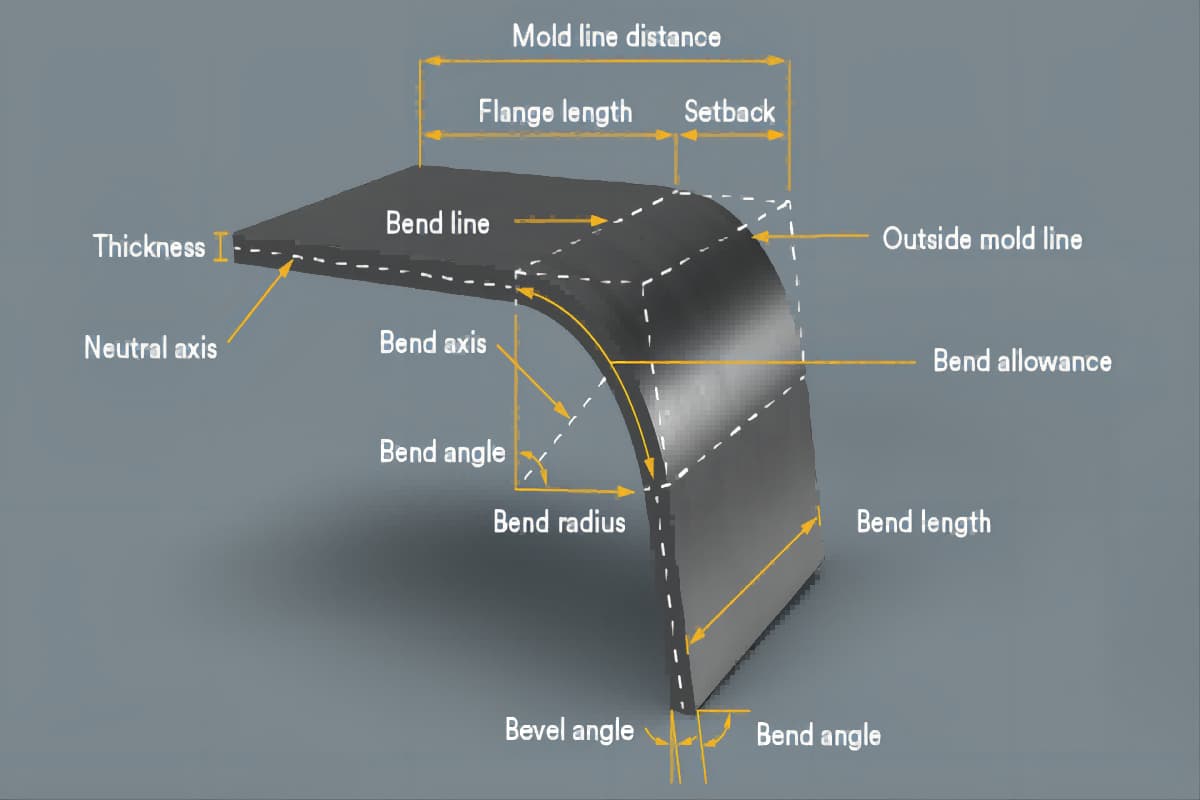

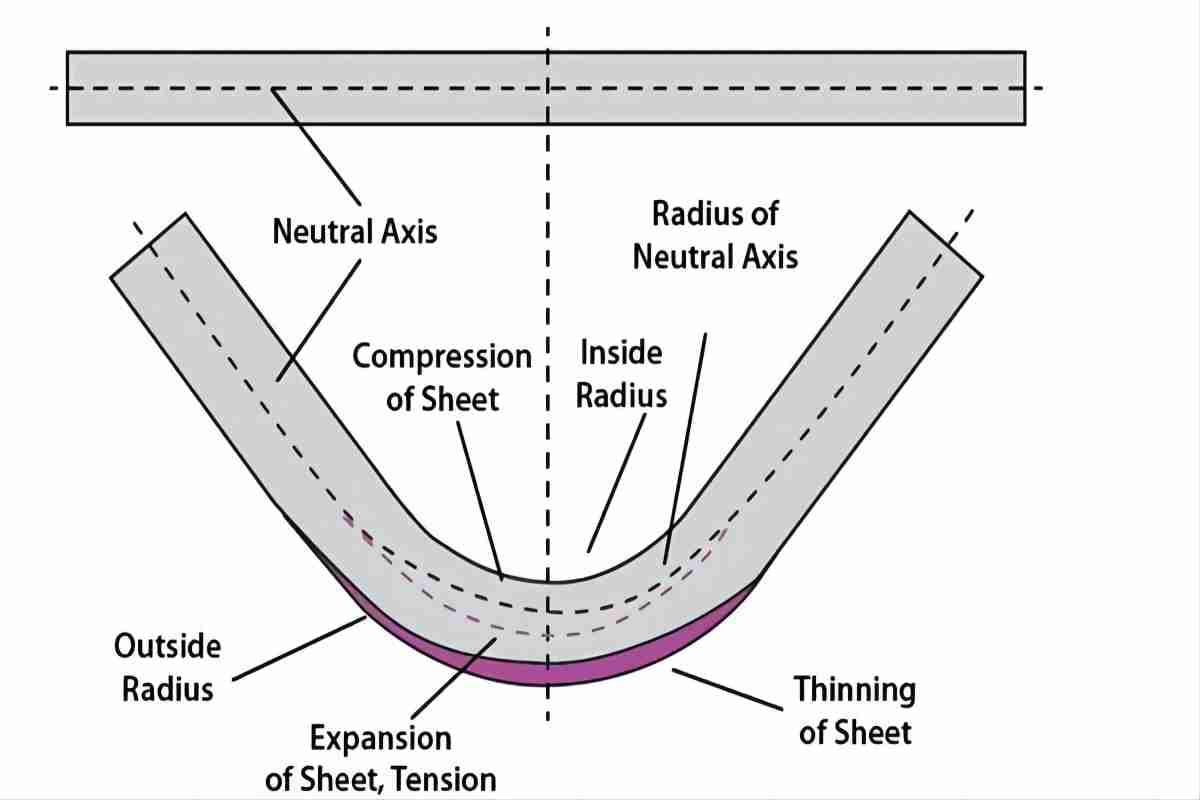

Press Brake bend radius, bend deduction, bend allowance, and K factor are critical parameters in sheet metal processing. Sheet metal processing is a comprehensive cold-working process for materials, typically below 6mm, such as steel, aluminium, copper, and other metal plates. The techniques involved in the metal forming industry include shearing, punching/cutting/compounding, bending, folding, welding, riveting, splicing, and forming, such as creating an automobile body. The defining characteristic of sheet metal processing is the consistency of thickness in the same part. Sheet metal bending involves changing the angle of the sheet metal, such as bending it into a V or U shape. There are generally two methods for sheet metal bending: die bending, used for complex structures with small volume and mass processing, and press brake bending, used for larger structures or small outputs. When metal materials are bent, the outer layer is stretched and the inner layer is compressed in its bend area. The smaller the inner bend radius, the more significant the tension and compression on the material. If the tensile stress on the outer bend exceeds the material's ultimate strength, cracking and fracturing may occur. The tensile strength and bend radius of the metal material both impact the quality of the final workpiece. To ensure high-quality bending, the structural design of the workpiece should avoid using a bend radius that is too small. The bend radius refers to the distance from the bend axis to the surface of the plate when bending metal plates or bars. This is commonly referred to as the internal radius. The external bend radius is usually equal to the sum of the internal bend radius and the thickness of the sheet. There are many factors that influence the bending radius of the sheet metal, including material strength, thickness, lower die opening width, and tonnage. In the bending process, the plate experiences both compressive and tensile stress, which also affects the press brake radius. The inside of the neutral axis is compressed, resulting in resistance to compression in the plate, while the outside of the neutral axis experiences tension, causing resistance to tension in the sheet. Upon removal of the workpiece, residual compressive and tensile stress cause springback, making the bending angle larger. Harder and thicker materials have greater springback, requiring over-bending to achieve a smaller angle than anticipated. When we air bend sheet metal, the size of the die V-opening determines the inside radius of the bend. In air bending, the inner radius usually is approximately 16-20% of the die opening width for 60 KSI cold-rolled steel and 20% for stainless steel. For material thicknesses less than 6mm, the inner radius is equal to the material thickness. The larger the V die opening, the larger bend radius. With the same V-shaped die, the greater the material's tensile strength, the larger the inner radius. The 8 times rule is a general guideline for determining the V-shaped die opening, suggesting that the V-die opening should be 8 times the material thickness. However, there is no exact formula for determining the ideal bend radius for sheet metal, but under certain specified force conditions, the bend radius can be estimated to be equal to the thickness of the plate. It's important to note that changes in the material thickness will affect the accuracy of this estimation. The V-shaped die opening may range from 6 to 12 times the material thickness. The bend radius is closely related to the material thickness. For material thicknesses less than 6mm, the bend radius is equal to the material thickness. For material thicknesses greater than 6mm but less than 12mm, the bend radius is typically 1.5 times the material thickness. For material thicknesses greater than 12mm, the bend radius is approximately 3 times the material thickness. The press brake bend radius can be calculated using the formula, all in millimeters: R = (V - MT) / 2 For example, if the V-opening width is 50 mm and the material thickness is 5 mm, the bend radius would be: R = (50 mm - 5 mm) / 2 = 22.5 mm It's important to keep in mind that these are just rough guidelines and there are many factors that can impact the bend radius, making it challenging to determine an exact number. When the sheet thickness is equal to the bend radius, the most ideal bend radius is achieved. The bend formed with this radius is consistent in angle and size and has minimal springback. If the bend radius is smaller, the stress on the outside of the bend will be greater and the tension will be greater. The plate will be deformed, cracked, or broken during bending. In order to avoid these problems, attention should be paid to the minimum bending radius. Due to different bending methods, die and material characteristics, different workpieces may have different minimum bending radii, and it is difficult to calculate the correct value. However, in order to obtain the most perfect bending workpiece, the inner radius should be set as close to the plate thickness as possible. To select plates with high ductility, the greater the tensile strength and hardness of the material, the larger the radius is required. Bend deduction refers to the amount of stretching that occurs during bending. It is calculated as the difference between the total length of the flange and the total flat length. Given: 1. Calculate Bend Allowance (BA) The formula for Bend Allowance is: Plugging in the values: 2. Calculate Outside Setback (OSSB) The formula for Outside Setback is: Plugging in the values: OSSB=3+2 3. Calculate Bend Deduction (BD) The formula for Bend Deduction is: Plugging in the values: 4. Summary: 5. Application: To achieve a 90° bend with a 3 mm inside bend radius on a 2 mm thick stainless steel sheet, you need to set the bend deduction to 3.9 mm during the bending process. This means you need to over-bend the sheet by 3.9 mm to compensate for the springback after bending, ultimately achieving the desired 90° bend angle. 6. Practical Example: Suppose you have a sheet metal part with two flanges, each 40 mm long, and a 100 mm base. The total length before bending is: After accounting for the bend deduction: Therefore, the flat pattern length should be 172.2 mm to achieve the desired dimensions after bending. Bend radius plays a crucial role in sheet metal bending, and the correct inner radius ensures the bending quality of the workpiece. The inner radius can also be used to calculate key parameters such as bend allowance and bend deduction. An improper natural inside radius can result in the deformation or even breakage of the workpiece. This article provides an overview of sheet metal bending. The use of the ADH press brake can help in producing more precise workpieces. If you have any questions about large radius bending or any other type of sheet metal bending on a press brake, please get in touch. Insulation Powder Coating HLM Powder Coating CO,.Ltd , https://www.holymepowder.comI. Introduction

II. What Is the Sheet Metal Bend Radius?

III. What Determines the Sheet Metal Bend Radius?

IV. Press Brake Bend Radius Calculation

1. What Is the Minimum Bend Radius of Sheet Metal?

2. What Is the Formula for Bend Deduction and Bend Allowance?

Step-by-Step Calculation:

OSSB=5 mm

V. Conclusion