With the laser cutting market becoming increasingly competitive, businesses face the challenge of choosing the right equipment and manufacturers that align with their specific needs. The purpose of this article is to provide a comprehensive overview of the top laser cutting machine brands, highlighting their strengths, innovations, and market presence. By examining the leading manufacturers in the industry, we aim to guide potential buyers in making informed decisions, ensuring they invest in machines that offer the best combination of quality, performance, and value. Here is the short video for watching: The laser cutting machine market was valued at approximately $5.89-5.95 billion in 2023. It is projected to grow significantly, reaching $11.32-14.21 billion by 2030, with a compound annual growth rate (CAGR) of 9.21-10.72% during this period. This growth is fueled by technological advancements and increasing adoption in sectors like automotive and aerospace. China dominates the global laser cutting machine market, accounting for 38.75% of the market share in 2023. The Chinese market is expected to grow at a CAGR of 12.44%, reaching $7.78 billion by 2030. The United States holds the second-largest market share at 16.27%, with a projected CAGR of 9.54%. Europe also maintains a significant presence in the market. Recent years have seen a shift towards fiber lasers, which offer advantages over traditional CO2 lasers such as higher efficiency, precision, and reliability. There is also a growing trend towards automation and integration of technologies like Internet of Things (IoT) and artificial intelligence (AI) in laser cutting systems. These advancements are enhancing productivity and reducing human intervention in the cutting process. Prominent players in the market include Trumpf, Bystronic, Mazak, ADH Machine Tool, and Amada, among others. These companies have established themselves as leaders through continuous innovation, extensive product ranges, and strong global distribution networks. When selecting a laser cutting machine, it's crucial to consider various factors to ensure that the equipment meets your specific needs and delivers the best value for your investment. Here are some key aspects to evaluate: The primary purpose of a laser cutting machine is to deliver precise, high-quality cuts. Consider the following: For example, fiber lasers typically offer higher precision for metal cutting compared to CO2 lasers, with positioning accuracies as fine as ±0.001 inches (±0.0254 mm). Modern fiber lasers can achieve kerf widths as narrow as 0.1 mm, enabling highly detailed cuts. The xTool P2, a CO2 laser cutter, can cut through 20mm thick acrylic in a single pass, demonstrating impressive capabilities for non-metal materials. Different laser types are optimized for various materials: Ensure the machine you choose can handle the materials you work with regularly. For instance, fiber lasers excel at cutting metals up to 30mm thick in a single pass, while CO2 lasers are better suited for non-metals, capable of cutting acrylic up to 25mm thick efficiently. The power output of the laser cutter directly impacts its cutting capabilities and speed: Higher power generally allows for faster cutting speeds and the ability to cut thicker materials. For example, a 5kW fiber laser can efficiently handle materials up to 25mm thick in mild steel, with cutting speeds reaching 15 m/min for 3mm stainless steel, making it suitable for medium-sized manufacturing operations. Evaluate the total cost of ownership, including: Prices can range from $3,000 for entry-level machines to over $1 million for high-end industrial systems. Consider your budget, production needs, and long-term business goals carefully. Factor in the cost-per-part and potential efficiency improvements when assessing the overall value. Reliable service and support are critical for minimizing downtime: Consider manufacturers with established support networks and comprehensive service packages to ensure maximum uptime and longevity of your investment. Consider the machine's flexibility and customization options: Look for machines that offer scalability and can be easily integrated into your existing or future production workflows. This flexibility can significantly enhance the machine's long-term value and adaptability to evolving market demands. In conclusion, choosing the right laser cutting machine brand is crucial for your business. By considering factors such as cutting quality, speed, power, and after-sales service, you can find the equipment that best suits your needs. Whether you're a startup or a large manufacturer, there are high-quality brands on the market that cater to your requirements. Speaking of top-notch laser cutting equipment, I'd like to recommend the products from our company, ADH Machine Tool. With over 20 years of experience in the industry, we have been dedicated to providing our customers with high-quality, high-performance sheet metal processing equipment. If you're interested in our products, I invite you to visit our product pages to learn more details. I believe that by choosing ADH Machine Tool, you'll find the perfect laser cutting machine that will bring even greater success to your business. Water Shooter,Plastic Water Shooters,Pool Water Shooter,Shark Water Shooter ZHOUSHAN SKYTOP COMMODITY CO., LTD. , https://www.bodyboard.com.cnI. Introduction

II. Market Overview and Trends

1. Global Market Size and Growth

2. Key Regions

3. Technological Innovations

4. Market Players

III. Top Laser Cutting Machine Brands and Their Offerings

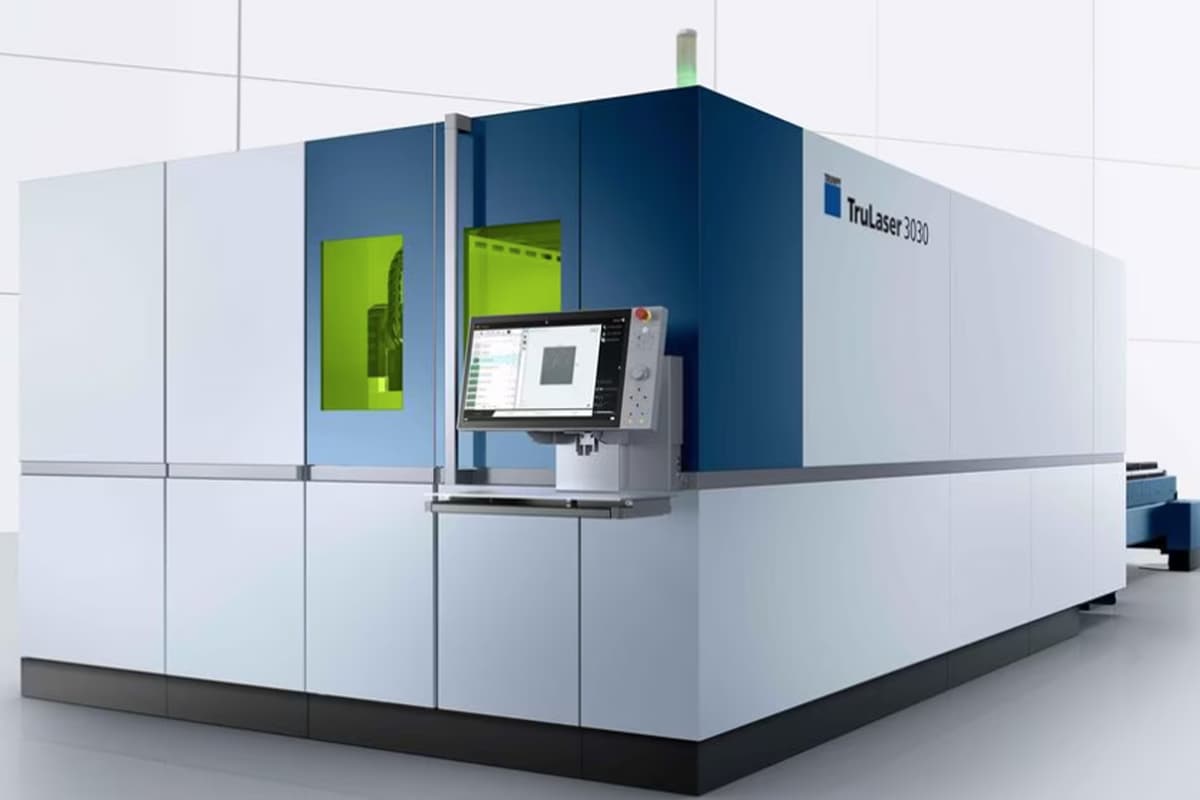

1. Trumpf (Germany)

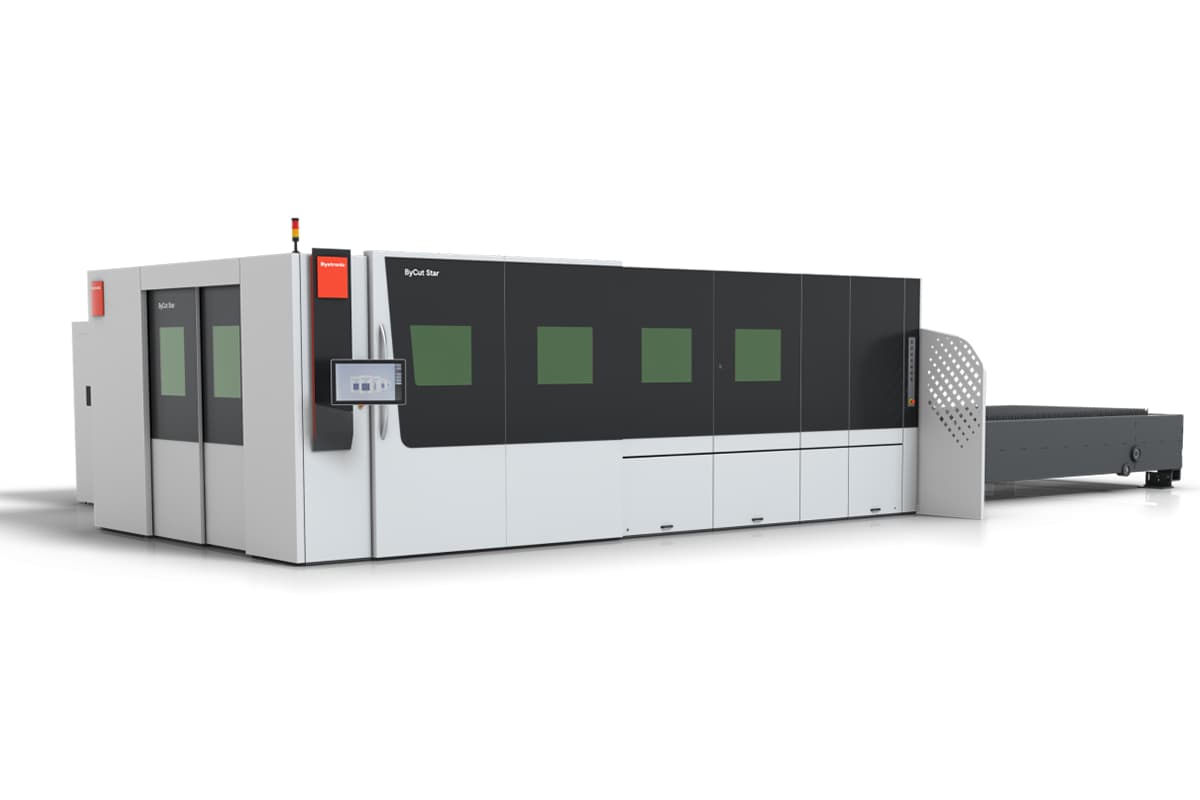

2. Bystronic (Switzerland)

3. Mazak (Japan)

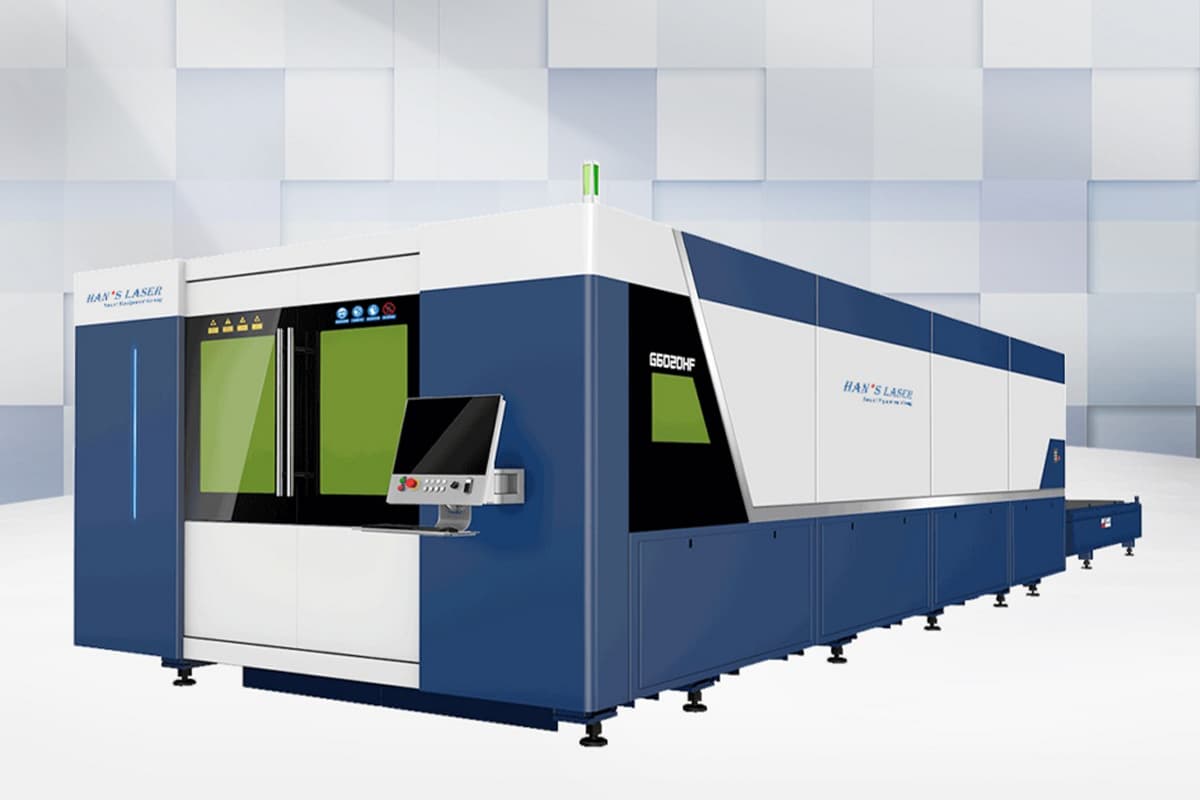

4. Han's Laser (China)

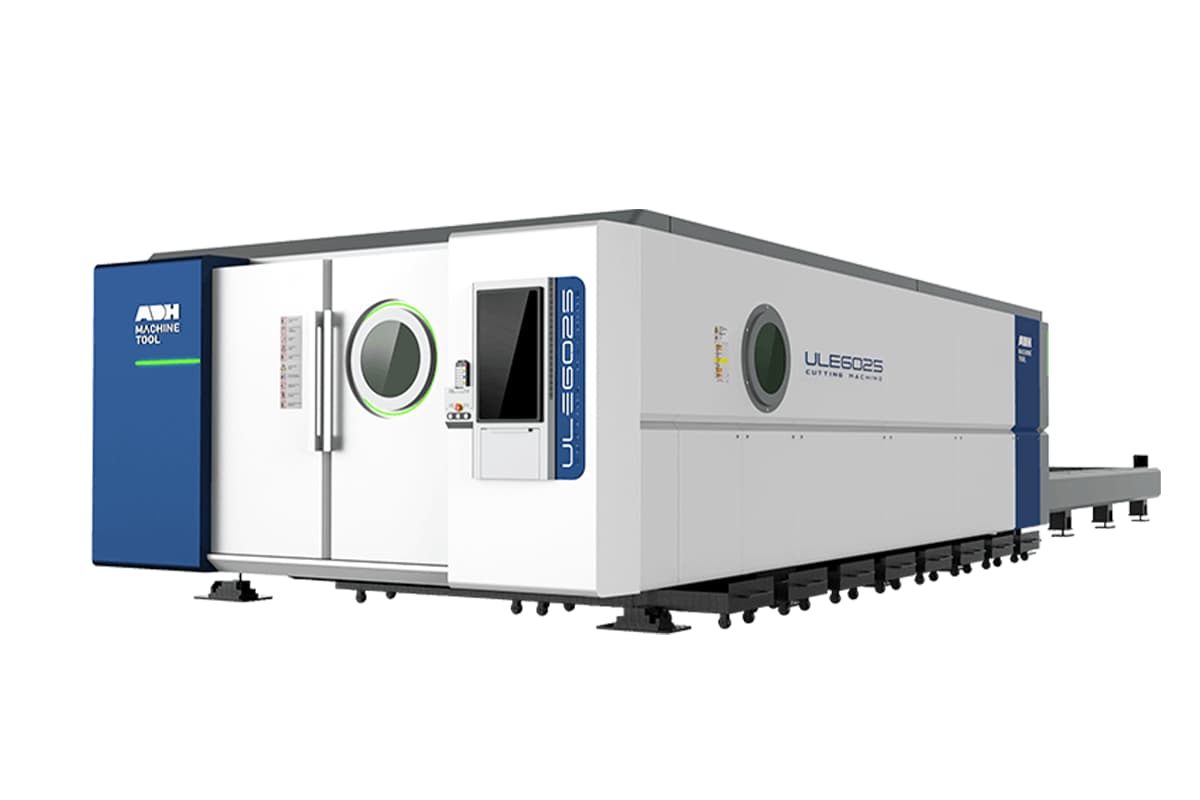

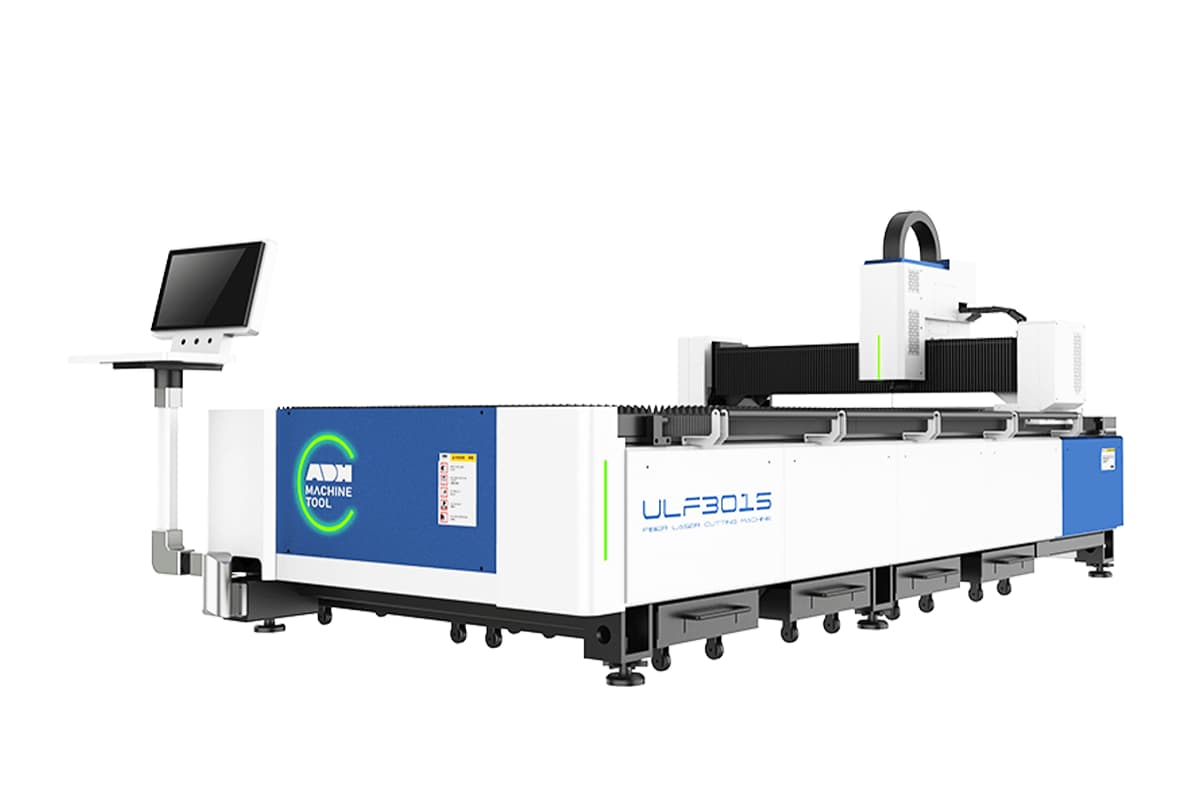

5. ADH Machine Tool (China)

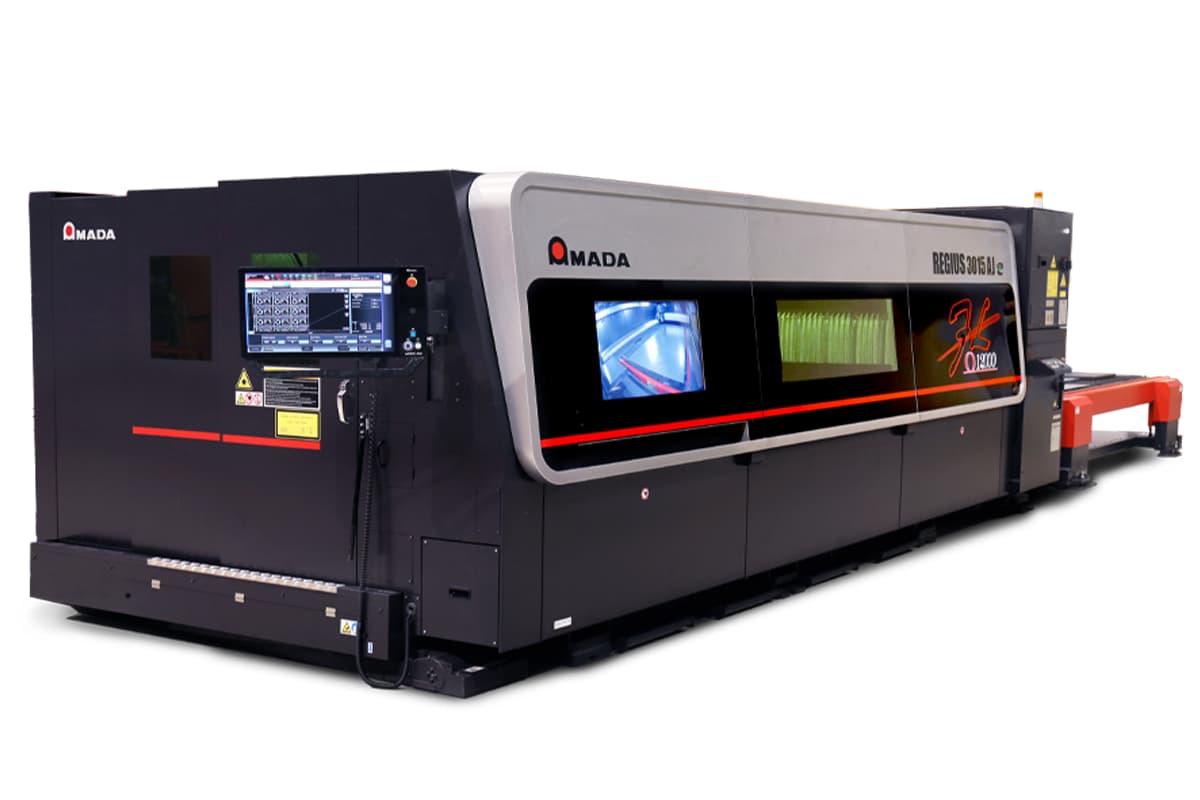

6. Amada (Japan)

7. Coherent (USA)

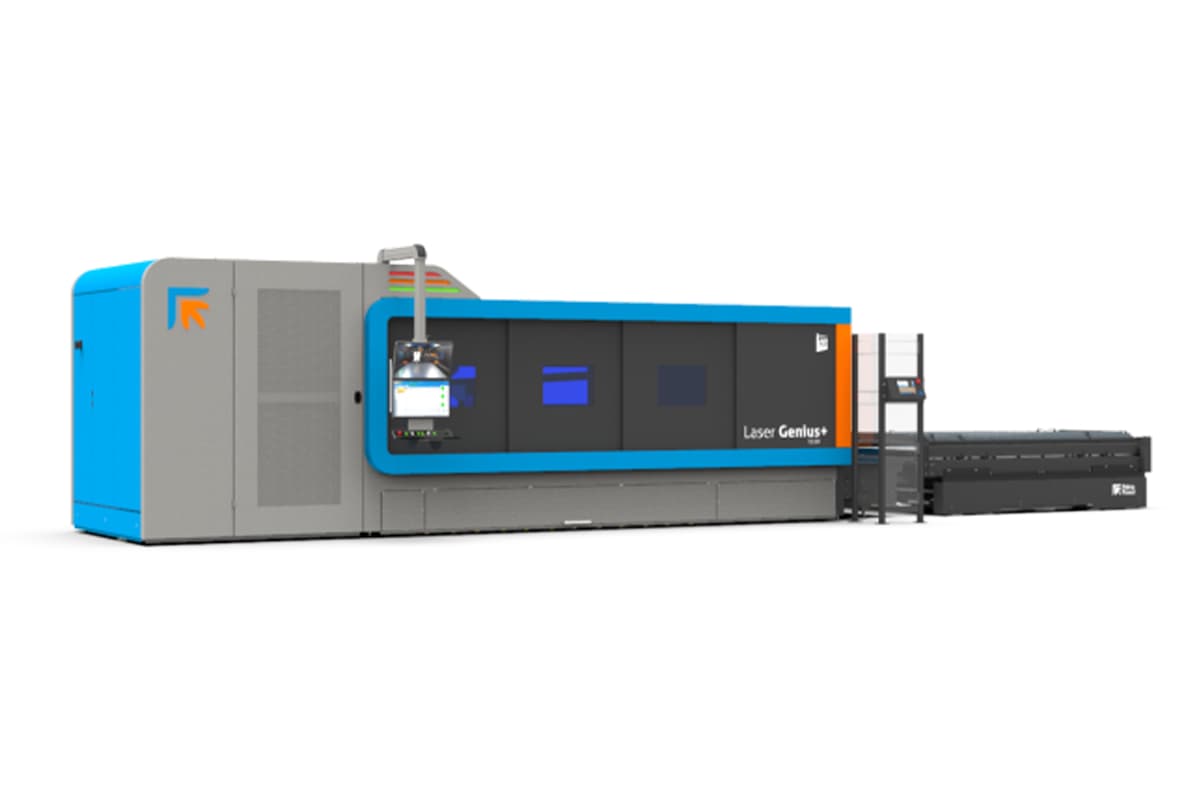

8. Prima Power (Italy)

9. Messer Cutting Systems (Germany)

10. Durma (Turkey)

IV. Factors to Consider When Choosing a Laser Cutting Machine

1. Cutting Quality and Precision

2. Material Compatibility

3. Power and Speed

4. Cost Considerations

5. Service and Support

6. Machine Customization and Integration

VI. Conclusion